|

|

|

Model IHP - Metric High Pressure Hydraulic Cylinders |

|

|

"Double Rod End Cylinders: / Y" |

|

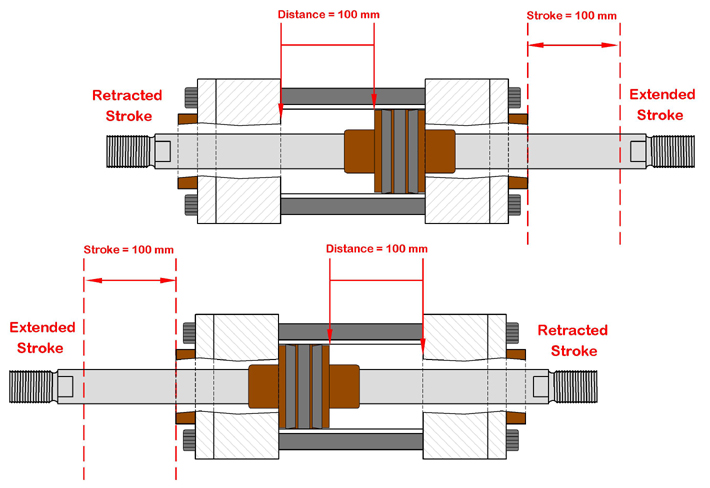

Peninsular Model IHP metric high pressure hydraulic cylinders may be ordered with piston rods extending out of both the front and rear cylinder heads (double rod end cylinders), thus, creating simultaneous push and pull linear movement at both cylinder ends. Please refer to the illustration below that shows an internal view of a double rod end cylinder capable of stroking simultaneously at both cylinder ends. The below illustrations represent a Double Rod End Cylinder that would be ordered with a 100 mm Stroke.

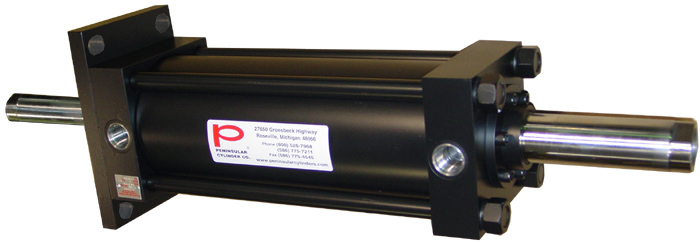

Peninsular Double Rod End Cylinder photographed in Mid Stroke Head Rectangular Flange Mount (MF1) at one end.

Although the vast majority of double rod end cylinders contain the same piston rod diameter at both ends of the cylinder, it should be known that occasionally Peninsular is called upon to manufacture these cylinders with different piston rod diameters and rod end threads at each cylinder end to suit a specific application. Should this be your requirement, please do not hesitate to contact us. There are hundreds of thousands of applications within the world of automated manufacturing systems that require the use of double rod end cylinders, and we have incorporated our improved double rod end design throughout our entire product line for over 50 years. The International Standards Organization (ISO) lists various standard cylinder mounting styles for single rod cylinders, however, not all of these mounting styles are suitable for double rod end cylinders, because many of these mounting adaptors are located on the back end of the cylinder.

The three mounting style charts below show the

Peninsular mounting styles that can be (1) configured and

manufactured (2) other mounts that can not be configured

within this configurator - just call us and we will configure

these mounts for you (and yes we do manufacture these) and (3)

cylinder mounts that cannot be made into double rod end

cylinders.

|

|

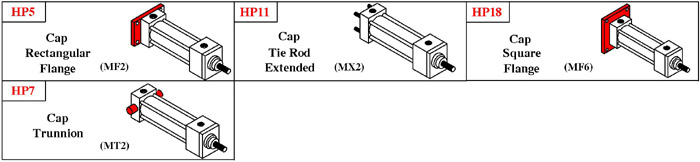

The following Model IHP NFPA High Pressure Hydraulic Cylinder Mounting Styles MAY BE CONFIGURED herein for Double Rod End Cylinders

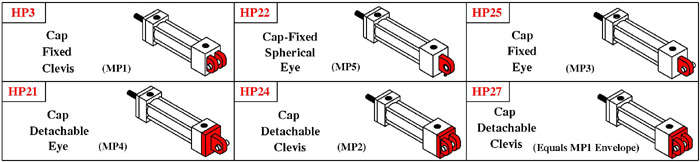

The following Model IHP NFPA High Pressure Hydraulic Cylinder Mounting Styles ARE NOT CONFIGURABLE herein for Double Rod End Cylinders Should a double rod end cylinder be required for one of the below cylinder mounts please contact us and we will configure it for you

The following Model IHP NFPA High Pressure Hydraulic Cylinder Mounting Styles CANNOT BE CONFIGURED OR MANUFACTURED into Double Rod End Cylinders

Toll Free: 800-526-7968 Phone: (586)

775-7211 Fax: (586) 775-4545 |